bull nose end mill definition

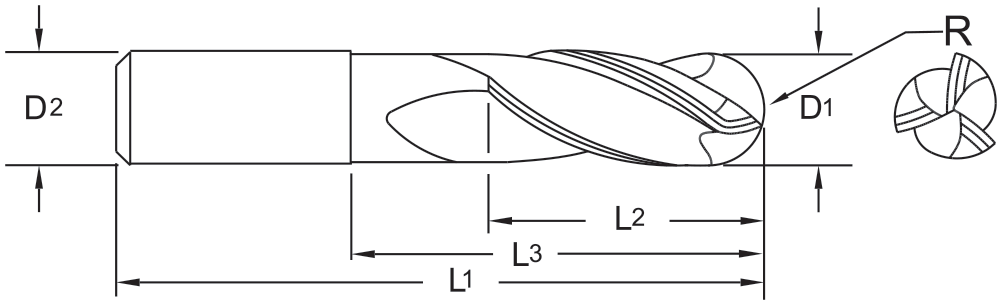

The end of this tool is ground with a full radius equal to half of the. It is distinguished from the drill bit in its application geometry and manufacture.

Bull Nose Mill 4rta020024 Bull Nose End Mill Bull Nose Mill Taiwan Product Manufacturer Supplier Exporter Www Endmills Co

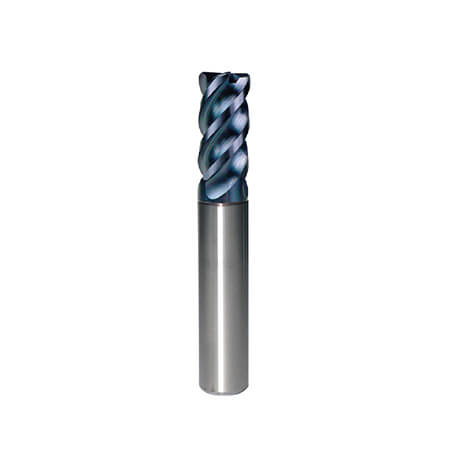

Our bull nose end mill mainly designs for machining HRC65 stainless steel SUS303 SUS304 SUS316L material.

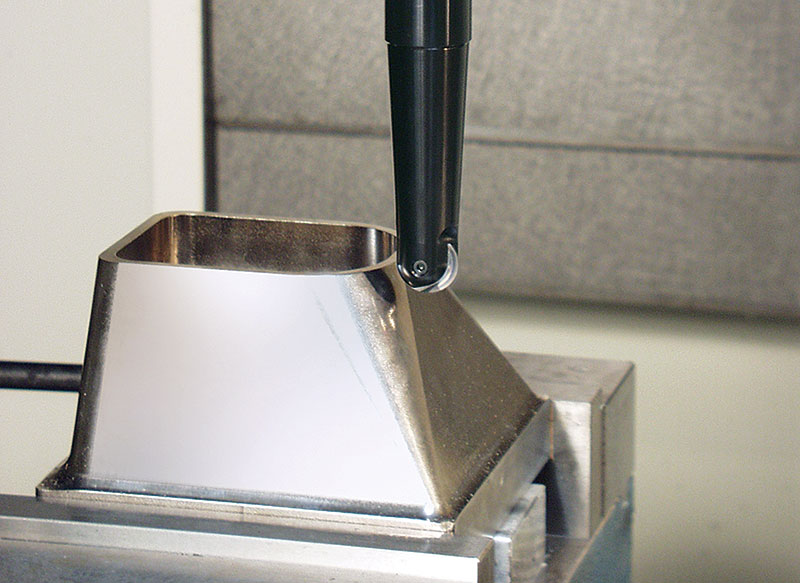

. Ball nose end mills are cutting tools used in milling applications such as profile milling tracer milling face milling and plunging. The bull nose end mill is a popular tool used in finishing milling operations. Bull Nose End Mills KDMT Bull Nose End Mills KDMT.

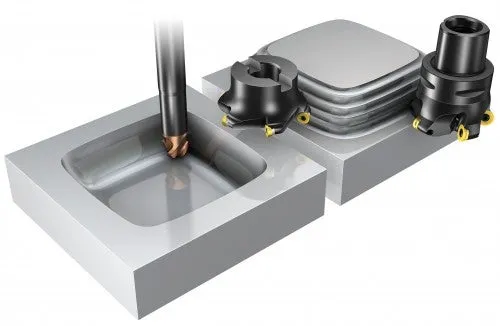

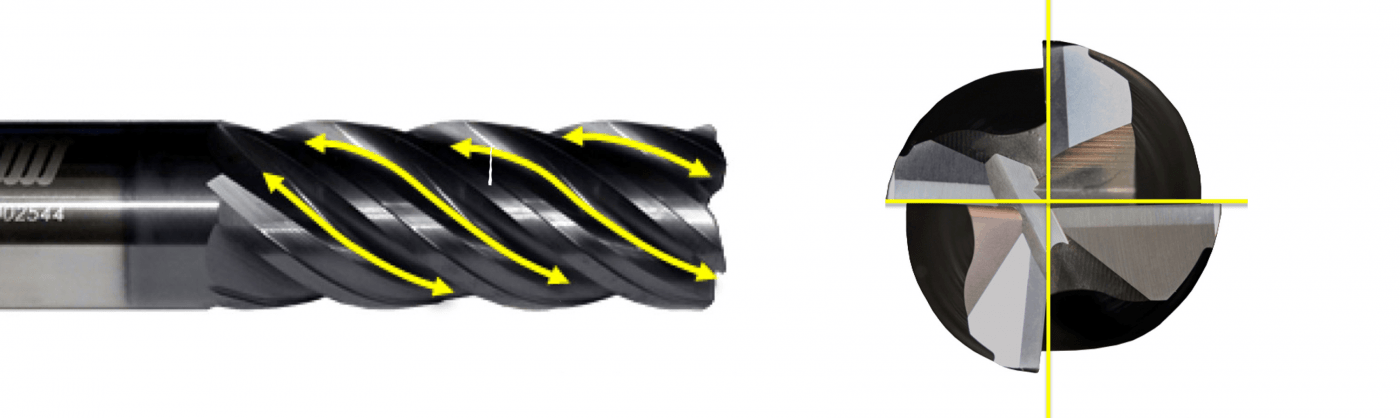

625 shows WEBNHE performing up milling operation. All are center cutting. Often used for slotting and pocketing cuts in mold and die making these end mills have a 90 profile and rounded corners which reduce flute breakage and chipping.

While a drill bit. Cobalt Steel Ball End Mills with Two Milling Ends. The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose.

A ball end mill is constructed of a round cutting. The bull nose end mill is a type of tool that is used in machining high-speed channels in metals. A photograph of the investigated WEBNHE is shown in Fig.

Ball End Mills Ball Nose Carbide Cobalt Hss. The tool is often coated with titanium nitride TiAlN to reduce friction and increase strength. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. Unlike conventional drill bits end mills have cutting teeth at. Flat bottom inserts cut an effective Z-level or plunge milling.

You can use it for profile milling cavity machining and spherical slot. With better heat and wear resistance than high-speed steel these cobalt steel end mills can run at higher speeds and provide better. Flat bottom and backdraft.

A useful derivative of the slot drill is the ball nose cutter again with two flutes and with end cutting faces carried slightly over centreVarious contours on workpieces are required in copy. A ball end milling cutter is also known as a ball nose mill. Mechanics of wavy-edge bull-nose helical end mill.

An end mill is a type of milling cutter a cutting tool used in industrial milling applications. This type of tooling features flutes with no flat bottom rounded off at the end creating a ball. It has two types of inserts.

Ball Nose Finish Milling Reference Troubleshooting Info Dapra Corporation

Customized Carbide Bull Nose End Milling Cutter R0 5 R1 0 R2 0 End Mills China Angle End Mill And Corner Radius End Mill

Helical Cutting Edges On The Tool Download Scientific Diagram

Machining Processes Used To Produce Various Shapes Milling Ppt Video Online Download

Ball Nose And Bull Nose Inserts Work Well Together Sterling Edge

Cnc End Mill Guide Cnccookbook Be A Better Cnc Er

Ad98 Diamond Coated Bull Nose End Mills 4 Flutes Standard Length Artco American Rotary Tools Company

M A Ford Tuffcut X Al 3 Flute Ball Nose End Mill Finisher Necked 3 8x1x2 1 8x4 M A Ford

High Speed Tapered End Mills Manufacturers And Suppliers Echaintool Precision

Types Of End Mills Difference Between End Mill And Drill Bit What Is End Milling Cnclathing

Cnc Basics Learn Module Unsw Making

Ball Nose End Mill For Roughing And Finishing American Machinist

Bull Endmill End Milling Cutters Imts Digital Platform

The Anatomy Of An End Mill In The Loupe

End Mills The Essential Beginners Guide

Basic End Mills Technical Information Msc Industrial Supply Co

How To Define A Corner Chamfer End Mill Autodesk Community Fusion 360